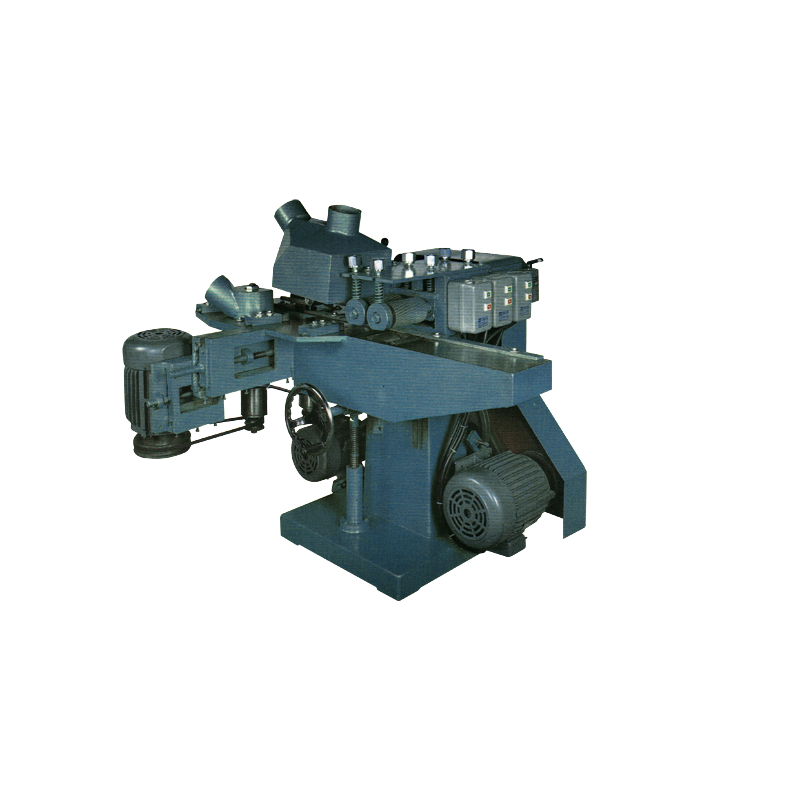

4"x 6" 3 Side Planer, Moulder

SM-3006

Features:

- Our most cost effective small to medium shop push-feed moulder.

- If you try to run your short runs of special moulding at lower prices, this machine could be your answer.

- Solidly built with cast and steel plate construction, this is one moulder that will give you a foot up on the competition at an affordable price.

- Precision cast and steel plate construction to ensure a smooth finished product.

- Two vertical and one 1-1/4" horizontal spindles driven by an individual industrial motor allowing smooth cutting on three surfaces simultaneously.

- Alloy steel spindle for durability usage.

- Two power infeed rollers feed the material to push previous pieces through moulding process then come out from the end.

- 2 belts driving at each spindle for maximum cutting power.

- Top and side pressure hold down to ensure smooth finish.

- Industrial full power motor for maximum cutting capacity.

- Precision sealed long-life bearing.

- Heavy cast iron frames and table for durability usage.

Specification:

| SPECIFICATIONS |

SM-3006 |

| Table Size |

47" L x 10" W |

| Moulding Capacity (Max.) |

6" W x 5" H |

| Moulding Capacity (Min.) |

¼" W x ½" H |

| Top Spindle Size |

35 MM x 6" L |

| Side Spindle Size |

1¼" x 3½" L |

| Spindle Travel |

3" |

| Spindle Speed |

7000 RPM |

| Feed Speed |

10' ~ 56' |

| Max. Cutter |

5" |

| Spindle Motor |

5 HP x 1, 3 HP x 2 |

| Feed Motor |

½ HP |

| Voltage |

220 V, 3 PH |

| Dust Hood |

4" x 4" |

| Overall Dimensions |

51" L x 43" W x 41" H |

| Top Pressure Rollers |

2 |

| Side Pressure Rollers |

3 |

| N.W. |

1210 LBS |

| G.W. |

1550 LBS |